"One advantage of 3D CG is that it is easy to convey well-investigated information. For this reason, we basically use Shade3D as a means of sharing information with people inside and outside the company". The company has focused on the functionality of 3D CG as a tool to refer its products to customers. By sharing carefully-reviewed information with customers, the company has realized benefits such as the effective use of limited meeting time. 3D CG is also used for in-house training and as a tool for discussing product development ideas.

Mr. Nakano, the New Product Development Dept, New Product Development Team 2 presents the perspective that animation can utilize time resources of information, such as movements, which are difficult to convey in writing alone. He then mentioned the features of Shade3D, which allow modeling, rendering, lighting, and video creation in one program. In addition, he also appreciates its superior cost performance compared to existing CAD systems. "Our company first introduced Shade 8.5 in 2006, and it had been used mainly for internal meetings about buildings and facilities even before I joined this department", says Mr. Nakano, who has been using the software since Shade R3 developed in the late 1990s. He transferred to this department in FY2022 and introduced Shade3D Ver. 22 at the same time.

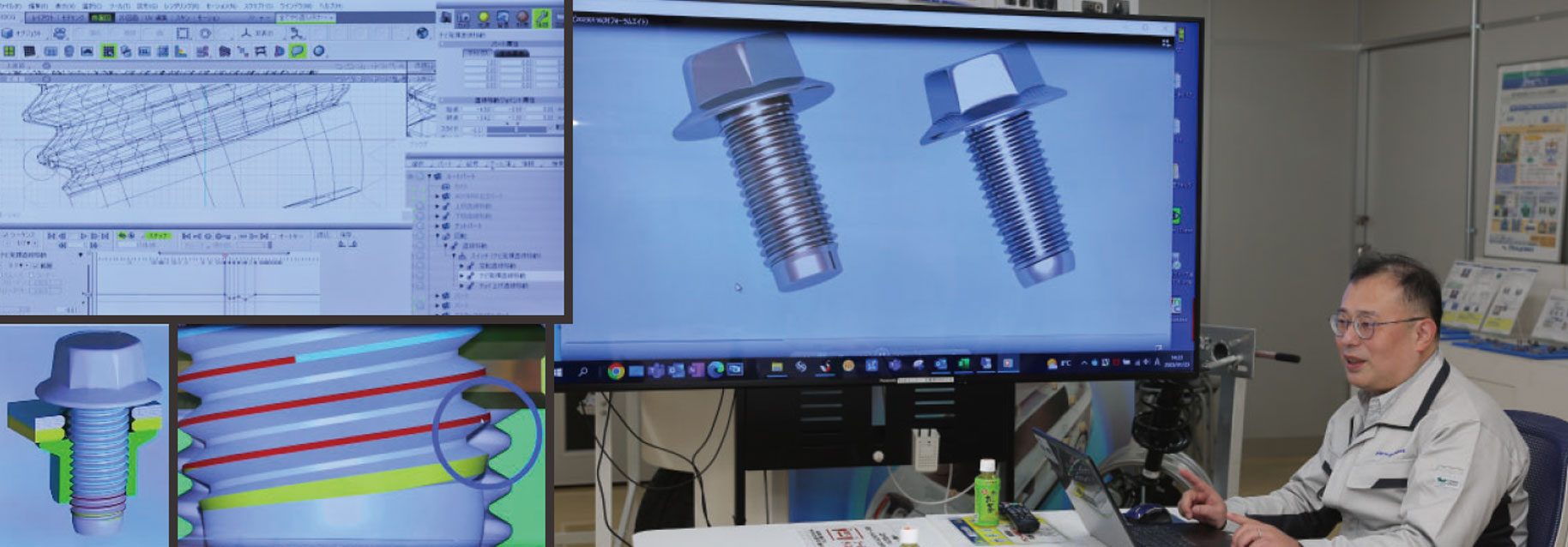

The first example of a major Shade3D application is an animation explaining the company's proprietary "R Navitite®" bolt to prevent skewed entry. While tightening an ordinary bolt at an angle causes a phenomenon in which the bolt cannot be tightened any further (seizure), this problem has been solved by adopting a special tip-shaped thread. However, because we cannot see the movement of the process inside, they could not give a clear image when explaining the mechanism. They used Shade3D and visualized in 3DCG how R-Navitite® inserted at an angle moves in a spiral motion inside the nut, which is normally invisible, and how the center of gravity shifts and rises up, and how it is correctly tightened. Previously, a video had been created using 3D CAD to explain the mechanism, but due to functional limitations, it could only reproduce the minimum movements necessary. Shade3D helped to reproduce the movements of the developed product in realistic detail, Mr Murakami explained.

Also, at an event called "Examining what is needed to build a lunar society", they created an animated video of the 4-wheel drive using Shade3D in order to share their ideas at "Examining the means to move around the Moon alone", for which the company was responsible among the various participating companies. This helped to unify the image (outline).

|

|

| Internal parts for various applications such as electric vehicles and aircraft are on display in the headquarters showroom. |

Similarly, they created CG models of the heat treatment facility for bolts in a factory for an external presentation on the company's efforts to improve energy efficiency. Using only the drawing data of the building and video of the equipment, they reproduced the realistic movements of the equipment by making full use of free-form surface modeling and swept surface functions, as well as spending time on lighting and light source settings.

Meanwhile, the company also created computer graphics for in-house training on its product, the piercing nut. The CG visualizes the structure of a plate being formed on the press line and the piercing nuts being sent from the parts feeder one by one or two by two to be attached.

In addition, the CG reproduced the operation of a SCARA (Selective Compliance Assembly Robot Arm) robot used in the company, also for the purpose of in-house training, is expected to be effective in making it easier to explain the functions of manufacturing equipment.

The company is expanding globally, with several overseas factories. "I believe that the work of tightening bolts and nuts is the same all over the world", said Mr. Oyama, explaining the usefulness of 3D CG as a tool for "the same explanation by anyone in any country", regardless of language differences, to customers not only in Japan but also around the world.

Mr Nakano also said that the high degree of freedom is the appeal of Shade3D. He expects Shade3D to be used as "a means (one of the tools) for sharing information" in various situations, both inside and outside the company. "I am sure that once people start using Shade3D, different applications and interesting worlds will open up", he said.

|

|

Mr. Murakami (left), Team Manager of New Product Development Team 2,

New Product Development Dept., Research & Development Group.

Mr. Oyama (right), Team Manager of Engineering Service Team 2,

Engineering Service Dept., Research & Development Group |

|

Visualizing the movement of a bolt inside a nut that is normally invisible with animation using Shade3D.

Mr. Nakano, New Product Development Team 2, New Product Development Dept. |

|