Introduction Introduction

|

|

COM3(Fiber) is one of a series of products of FORUM8 for the nonlinear

analysis of reinforcement concrete structures under static and dynamic

loads based on the RC constitutive model which is developed by the Concrete Laboratory, University of Tokyo. It is a following product of WCOMD, which can carry out the two dimensional

dynamic nonlinear analysis of a plane RC structure. COM3(fiber) is furthermore

extended to the three dimensional nonlinear analysis of any spatial RC

structures or RC components that can be modelized as a fiber element, especially

for bridge piers and constructional columns or beams. |

|

Page Top  |

|

Outline and Features Outline and Features

|

|

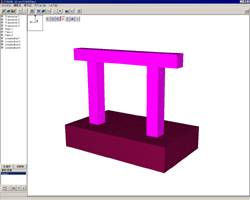

The complexity of three dimension simulation of RC materials in the non-linear

response range is overcome by COM3(Fiber) through using a fiber model element,

which condense a cell-constituted section to a beam point defined as a

fiber element and then is computed as a frame model. The section of element

is assumed as maintaining a plane and its materials and geometrical distribution

of steel and concrete are given in the section definition . The nonlinear

performances of concrete and steel obey the defined constitutive relationship

including the crack occurring judgment and post crack characteristics.

Besides of the fiber element, an elastic isosolid is employed to cast the

components that only present a linear performance during a forced period.

This can make users focus computation on the strong nonlinearly performing

parts of structures, save calculating time and disk space, and obtain a

satisfying result.

The static and dynamic loads can be applied to the structural model and

its responses such as displacements and strains can be displayed in an

animation form. The earthquake waves in the three directions can be edited

or input from a real history record. The damage states of Light damage

and Damage are defined with the strain level of Concrete and Steel. The

damaged fiber elements due to their experienced maximum strains can be

seen clearly with color. The acting forces on Gauss section of Fiber elements

are compared with Bending capacity and Shear capacity respectively at each

step. These results are shown by Graph and Tabular form for easy checking.

The analysis results can be exported in simultaneously printing or HTML

file form by selecting the corresponding table button.

COM3(Fiber) is a long time research achievement of the Concrete Laboratory,

University of Tokyo on the concrete constitutive model and its application

to FEM. The related research results are well published in the world and

highly evaluated not only in Japan but also oversea for its good accuracy

and effectiveness in the numerical simulation of RC structures. The interface,

creating model and past treatment, designed by FORUM8 make its operation

more easy and result study more intuitive. This product is retained jointly

by FORUM8 Inc. Co. and the Concrete Laboratory, University of Tokyo.

COM3(Fiber) not only provide user a precise response results of RC structures

at linear and nonlinear range under static and dynamic environmental loads

but also supply an enjoyable view of spatial results of cold world. By

using COM3(Fiber), users can successfully finish the project safety investigation

and at the same time receive a deep understanding on the complicated performance

in a heavy solid RC block. For researchers, COM3(Fiber) results can serve

as a theoretical solution for comparing with the experimental data and

a comparable object for interpreting a novel RC simulation model or method.

|

|

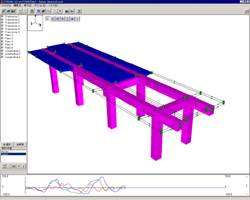

Structure model establishment Structure model establishment

|

|

|

Analysis results Analysis results

|

Cell results Cell results

|

Page Top  |

|

Usage Process Usage Process

|

|

As any FEM software, COM3(Fiber) also obeys the procedure from creating

models and defining loads to executing calculation and displaying results.

The window application interface provides many menu items, buttons and

function key to finish the procedure. Especially for the results presentation,

a colorfully and spatially visual display is enjoyable.

Unlike WCOMD which is divided into two main windows for creating model

and displaying results respectively, COM3(Fiber) finishes all the procedure

in one main window and some sub windows can be setup through menus , buttons

or left and right mouse button to define a specific item.

The general 4 processes and their relative buttons are listed below.

|

|

Model create Model create

|

Section editor Section editor

|

|

Dynamic load editor Dynamic load editor

|

Static load definition Static load definition

|

Page Top  |

|

System Requirements System Requirements

|

|

Operating System

- Microsoft Windows NT 4.0.(Service Pack‚S or later)

- Microsoft Windows 2000

Hardware

- Personal Computer:

PC/AT or PC/AT100 or compatible (Pentium 300MHz or higher).

Memory

Hard Disk

- This program requires at least 200MB free space (including the result calculation

file) for the installation of the product.

- You must also have sufficient free hard disk space for your own database

requirements.

Display

- Screen size: 20 inch or greater

- Screen resolution: 1024 x 768 or greater

- Colour: 64k

- Use both Design of Display and Display Font with default settings.

Hardware Protection Key

In order to use the full Product Version you must install the hardware

protection key provided by Forum8. Attach the hardware protection key to

the printer port (Parallel port) or USB.

If you start the program without the key attached, only the Viewer Version

of the product will be available. |

|

|

Order/Contact us Order/Contact us

|

|

|

|

Page Top  |