International Newsletter vol.43 2011/2

2.28.2011 FORUM8 Co., Ltd. http://www.forum8.com/

|

| New Product Information - Engineer's Studio(TM) Ver.1.06.00 |

|

Price: US$3,300(Base)/Free revision

up

Release date: December

2010 |

Dynamic

Nonlinear Analysis |

|

In Engineer's

StudioTM Ver 1.06.00, the following three functions have been

added/improved. All of them are the features for free revision up.

- Solver

- Plate Element Input & Output

- User interface performance for large models

|

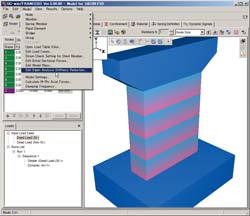

The PARDISO(Parallel Direct Solver) Sparse Matrix Solver (supported by the

Intel MKL library) has been implemented in the solver. PARADISO was originally

developed by the University of Basel, Switzerland. It greatly increases the

performance of the solver on large models. Memory usage is significantly reduced

and calculation times are significantly improved .For example, a 45000 node

model (plate elements, material nonlinear, static analysis, 50 steps) (Figure1)

uses 3GB of memory compared with 20GB in the previous version. This model

calculates in 30 minutes compared with 20 hours in the previous version. Eigen

analysis uses less than 1GB of memory whereas the previous version required

memory amounts beyond the limits of typically available desktop PCs and could

not run. This model calculates in one minute compared with an estimated two

hours in the previous version if memory had been available. This new feature in

conjunction with the previously released 64 bit solver option has significantly

increased the model size capabilities (number of nodes) of Engineers Studio.

Plate element models typically generate larger node counts than frame element

models. The PARADISO solver performs excellently over the full range of model

sizes typically found in Engineers Studio.

The initial stiffness of the

asymmetric bilinear spring has been changed from zero to the primary stiffness.

This spring type is typically used to model bilinear soil to concrete structure

interactions and with this improvement the model will now be stable in its

initial state. This means that the boundary conditions for the whole model can

be described by only the soil/structure interaction and previous remedies such

as dummy springs of small stiffness are no longer necessary.

The previous

restriction of 1000 child nodes per rigid body element has been removed. There

is no restriction now.

|

Figure1:45000 node model Figure1:45000 node model |

|

| Plate

Element Input & Output |

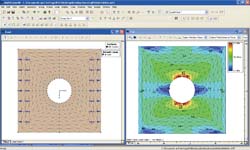

A new generator command was added to quickly create distributed nonlinear springs over surface areas of plate elements. Soil property profiles including layer thickness and stiffness (kN/m3) are input and all required spring definitions, spring elements, nodes and support conditions are automatically generated at each node of the plate elements selected.(Figure2a, b). This involves the integration of the stiffness over the element shape to produce equivalent node stiffness values. These integrals are calculated and the required spring definitions automatically generated.

A new feature was added

to the plate element loading feature. Offsets from the sides of the loaded

region are now possible. This gives control in 2D over the surface and enables

partial loading completely within a single element. (Figure3)

Maxima for

contour plots of the results of plate elements are now prepared per user defined

group (Figure4). Previous versions stored and reported the maxima for contour

plots over the whole model. Fibre strain results for fibre elements are now

prepared per group to give consistent treatment of strain results between plate

elements and fibre elements. A new delete function was added to the edit window

of the plate element "mesh element editor". Now when multiple primitives are

selected by the mouse they can be deleted by the delete button or from the right

click menu delete option. The option to delete unused nodes after deleting

primitives is also included in the new command.

Improvements to the plate

element creation from outlines were done. Now nodes in existing elements can be

optionally included in the mesh creation of the new element. This permits much

easier building of a correctly connected model. The result of load case

combinations are now shown for the contour figures of plate element

models.

|

|

|

Figure2a:Ground spring automatic generator Figure2a:Ground spring automatic generator |

|

Figure2b:Input of soil stiffness property Figure2b:Input of soil stiffness property |

|

|

|

Figure3:Bilateral offset function of plate loads Figure3:Bilateral offset function of plate loads |

|

Figure4:Contour Figure per group Figure4:Contour Figure per group |

|

| User

interface performance for large models |

Large plate element models typically require much higher node

counts than beam models. Many improvements have been made to improve the

response of the user interface on large models. Models of around 45000 nodes are

now manipulated with ease.

In models with many load steps and many cells

in a fibre section, the display of the fibre section results was very slow.

Improvements have been made. This data caused performance problems when reading

and writing files.

The process speed of the following items is improved.

- Input window access from [Input navigation]

- Result display of frame element

- Improved speed of 3D model drawing

- Range selection of a large number of nodes and element

- Result display of fibre element

- Reduced size of input data file

- Improved speed of file loading

|

|

|

Figure5:Image of Engineer's StudioTM Figure5:Image of Engineer's StudioTM

User forum to be

opened |

|

|

|

|

| New Product Information - UC-win/FRAME(3D) Ver.5 |

|

Price: US$6,800(New purchase)/US$1,000(Version up)

Release date: January 2011 |

|

UC-win/FRAME(3D) is a

general-purpose 3D frame analysis program. The Advanced version, a

top-of-the-line software allows static and dynamic analysis considering both the

material nonlinearity and geometry nonlinearity. It has some verification

functions including allowable stress, bending strength, shear strength, and

nonlinear member.

For this time, the following three functions are

added.

|

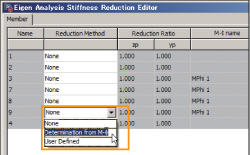

| Reduced stiffness in the eigenvalue analysis(Automatic calculation of yield

rigidity) |

The following sentences are stated in the expository writing of

"6.2.3 Calculation method of eigen cycle", "March 2002 Highway Bridge

Specification V Seismic Design Volume, dynamic verification with wide

application range, Japan road Association".

| As for the stiffness of bridge pier ------(snip)------, the yield rigidity

of bridge pier is used for the verification of seismic capacity for the

level2 earthquake. |

It is designed

to fulfill the seismic capacity of the whole bridge by absorbing the energy due

to the plastic member when the strong earthquake such as level 2 occurs. When

the plastic performance is applied for the member, the stiffness is reduced and

the eigen cycle is becoming long. Though it is necessary to calculate repeatedly

to analysis exactly based on the expository writing of the Highway Bridge

Specification.

In the previous version of FRAME(3D), the yield rigidity was automatically

calculated from the section shape and acting axial force by setting "bilinear"

or "linear" as the M-φ property category, and the eigen cycle was calculated. When "Tri-linear"

or "Tetra-linear" is selected in the category and the eigenvalue

analysis is performed, the obtained eigen cycle is the value which is calculated

with the cracked stiffness.Therefore, when the time history response analysis

is performed with "Tri-linear" or "Tetra-linear", it

was necessary to prepare the separate model for the eigen cycle calculation.

For

this time, the switch is added to use the yield rigidity for eigenvalue analysis

in these cases.It is unnecessary to calculate the yield rigidity

separately.

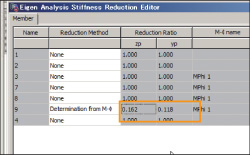

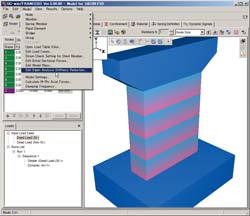

- Select "Edit the stiffness reduction value in eigenvalue analysis"

from model menu(Figure1).

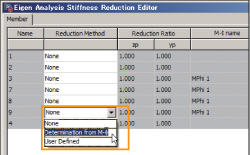

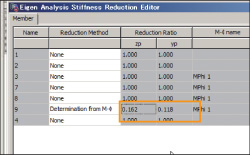

- Select the element to be reduced and choose the method for it.

It is possible to select from the method where the ratio of cracked stiffness

and yield rigidity from M-φ property is automatically calculated to use

it the reduction ratio or the user defined method(Figure2).

|

|

|

|

|

|

Figure1:Selection of model menu Figure1:Selection of model menu |

|

Figure2:Selection of the element to be reduced and method Figure2:Selection of the element to be reduced and method |

|

| Support for

Railway live loading |

UC-win/FRAME(3D) has the function of influencing line analysis and the

loading type was mainly based on the Highway Bridge Specification.

For this

time, it is improved to input EA loading based on "April 2004 Railway Structure

Design Specification, Concrete Structure".

The EA loading is the combination

of axle load group (multiple concentrated load) of the tracked train and the

load of tracked goods train.

|

Figure3:EA loading input image Figure3:EA loading input image |

|

| DWG/DXF output of model and section force |

DWG/DXF format is supported for the model and section force diagram after

calculation. Therefore, they can be edited with CAD software(Figure4).

|

|

|

Figure4:Moment(Left: UC-win/FRAME(3D). Right:DWG file) Figure4:Moment(Left: UC-win/FRAME(3D). Right:DWG file) |

In the analysis model, the fulcrum conditions are displayed as well as

the element(Figure5).

|

|

Figure5:Model diagram(Top: UC-win/FRAME(3D), Bottom: DWG file) Figure5:Model diagram(Top: UC-win/FRAME(3D), Bottom: DWG file) |

|

|

|

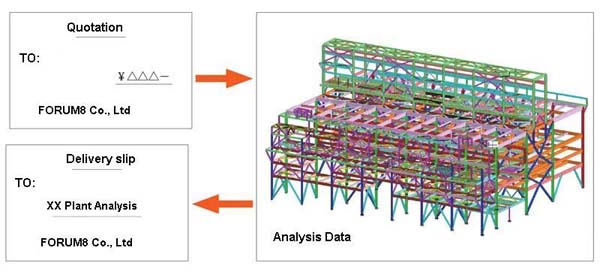

| Architectural and Structural Analysis Support Service |

|

Architectural and Structural

Analysis Support Service |

|

Multiframe,UC-win/FRAME(3D),Engineer's Studio(TM)Analysis Support

Service |

|

Start of the service: October 2010 |

|

FORUM8 is providing both architectural analysis support service as well as

the existing structural analysis. Multiframe, UC-win/FRAME(3D), and Engineer'sStudio(TM)are used

for this service.

|

We will first request for the structural drawing and the load case for

the cost estimation. Next, the estimation sheet is submitted to the customer.

After confirmation of the analysis contents and the estimation cost, our

technical staff will start working.

Our technical staff creates the analysis data

together with the customers to provide the appropriate analysis result where the

input data, optionally section force data are sorted out. We will provide

support for any inquiries after submission of the analysis data.

|

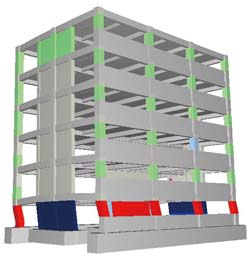

Multiframe is the structural engineering analysis software developed by

Formation Design Systems in Australia. Its first version was released for

Macintosh and this software has been used by more than 3,000 users in all over

the world. It allows the section calculation based on the standard in each

country. In Ver.12, it supports for the plane elements to perform a wider range

of analysis.

|

| What is

UC-win/FRAME(3D)? |

UC-win/FRAME(3D) is the 3D analysis program for space-framed structures. The

Advanced version allows the static and dynamic analysis based on the material

nonlinearity and geometric nonlinearity.

It has various verification features

for the allowable stress, flexural capacity, shear capacity, and nonlinear

members. Our analysis support team won the contest sponsored by the National

Research Institute for Earth Science and Disaster Prevention in Japan : "C1-2

E-Defense Pre-analysis contest of Full scale RC Pier Earthquake Resistance

Experiment, fiber model" with

UC-win/FRAME(3D).

|

| What is

Engineer's Studio(TM)? |

Engineer's Studio(TM) is the 3D plate dynamic nonlinear analysis program.

The function for nonlinear plate elements is added to UC-win/FRAME(3D). The

constitutive law of WCOMD which was developed by the concrete laboratory in

Tokyo University is applied for the nonlinear RC plane elements.

Our analysis

support team won the contest sponsored by the National Research Institute for

Earth Science and Disaster Prevention in Japan : "C1-6 E-Defense Pre-analysis

Contest of Full scale RC Pier Earthquake Resistance Experiment using nature

mortar" with Engineer's Studio(TM).

|

|

| Conferences, training and seminars |

| Upcoming Events |

|

Seminars in Shanghai,

Beijing and Seoul will be held on the following

schedule.

Venue:

Shanghai - Shanghai

Seminar room (FORUM8 Technology Development(Shanghai) Co.,

Ltd)

Seoul-FORUM 8 Korean

Office

| Seminar |

Date |

City |

| UC-win/Road

VR |

March 9th, 2011 |

Seoul |

| May 6th, 2011 |

Shanghai |

| UC-win/Road

SDK |

May 17th, 2011 |

Shanghai |

Engineer's

Studio(TM),

Engineer's Studio(TM)(2D)) |

March 24th, 2011 |

Shanghai |

| April 13th, 2011 |

Seoul |

| VR-Studio(TM) |

April 7th, 2011 |

Shanghai |

| EXODUS / SMARTFIRE |

March 3rd, 2011 |

Shanghai |

| May 10th, 2011 |

Seoul |

| xpswmm |

March 16th , 2011 |

Seoul |

| OSCADY/TRANSYT |

March 10th, 2011 |

Shanghai |

| March 23rd, 2011 |

Seoul |

| Design Builder |

March 30th, 2011 |

Seoul |

| Retaining wall design Ver.2 /Temporary sheating

work design Ver.2 |

March 17th , 2011 |

Shanghai |

| April 20th, 2011 |

Seoul |

| Participation Fee |

| Participation Fee |

Free |

For more information and applications, please email us

at

mailto:forum8@forum8.co.jp

Gross circulation: 5518

To

subscribe this page, go to http://www.forum8.co.jp/english/p-mail-e.htm

If

you would like to unsubscribe from our newsletters, please include

"Unsubscribe"

in the subject title of your email and send it back to

us.

Thank you for your continued support.

FORUM8 Co., Ltd.

mailto:forum8@forum8.co.jp

2-1-1 Nakameguro GT Tower 15F

Kamimeguro

Meguro-ku Tokyo 153-0051 JAPAN

TEL +81-3-5773-1888

FAX

+81-3-5720-5688

http://www.forum8.com/

|